City of phoenix lift station 77

Secondary Containment- A Systems Approach to Durable Chemical Resistance

PROJECT INFORMATION

Project Location

Phoenix, AZ

Project Completion Date

2022

Owner

City of Phoenix

Engineer

Wilson Engineers

The City of Phoenix is rapidly expanding and is challenged by keeping up with enough water & wastewater treatment facilities. Phoenix has become a target city for new manufacturing and industrial facilities. When an extremely large microchip manufacturing facility began construction, there arose a need to build new assets to handle the wastewater stream.

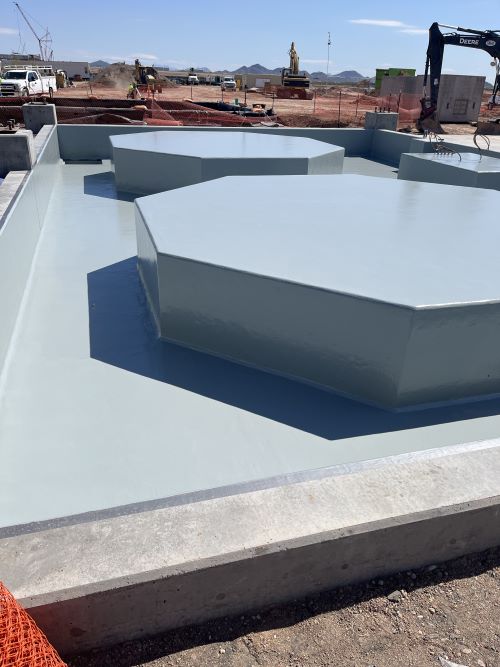

Lift Station 77 was built in 2022 to service the microchip plant. AO Painting applied the Tnemec 239SC Chembloc Mortar Reinforced Mat (MRM) secondary containment system. The need for a secondary containment system is more than just applying chemically resistant coatings. The 239SC system provides protection from chemicals along with impact resistance, abrasion resistance and resistance from cracking.

Following best practices, the concrete was profiled to an ICRI CSP-5 or better and Tnemec Series 218 MortarClad, an epoxy modified cementitious repair mortar, was applied to create a paintable surface and help eliminate outgassing. The 239SC novolac resin was used to make a mortar base coat ensuring chemical resistance throughout the system. Fiberglass is then embedded into the wet mortar and saturated with more novolac resin. Tnemec Series 282 Tneme-Glaze, a highly chemically resistant novolac epoxy, was applied in two coats for an aesthetically pleasing, chemically resistant surface. The system was finished with a coat of Tnemec Series 290 CRU, a chemical resistant urethane, to provide long term protection from the strong UV exposure of Phoenix, AZ.

Contact us today for help specifying durable, chemically resistant secondary containment systems.

Check out these other resources

Secondary Containment Coatings- What you need to know

Forklift Traffic on Warehouse Floors

Moisture Vapor Transmission Protection for Concrete Floors

Spalling Concrete and How to Fix It

Floor Coatings Are Not Easy to Specify

Selecting the Right Traffic Coating

Concrete Outgassing and How to Prevent It

Considerations Before Coating Concrete Floors

Selecting Coatings for Secondary Containment

Static Dissipative Floor Coatings

Advantages of Polyurethane Cement Coatings

Exploring Decorative Resinous Flooring Options

UV Resistant Epoxy Floor Coatings

Don't miss these flooring project profiles

Secondary Containment Systems in the Southwest

Manufacturing Facility With Flair

Manufacturing Facility Drum Floors and Walls

Town of Gilbert NWTP Containment

MORE HIGH PERFORMANCE COATINGS PROJECTS

High School Concessions and Restroom Floors

Steve Elliott and his team with Southern Painting and Maintenance Specialists did a great job of...

Market Type:

Bellingham Washington Airport Hangar Floor

This project was undertaken for a private aviation hangar in Bellingham, Washington. The client...

Market Type:

Manufacturing Facility Resinous Flooring...

This project was yet another home run from the Decorative Concrete Resurfacing (DCR) team located...

Market Type:

OR

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL