What Considerations Should an Architect Make Before Spec'ing Coatings

Before specifying a high-performance coating, architects should be aware of many considerations.

- High Performance Coatings

Before specifying a high-performance coating, architects should be aware of the following considerations:

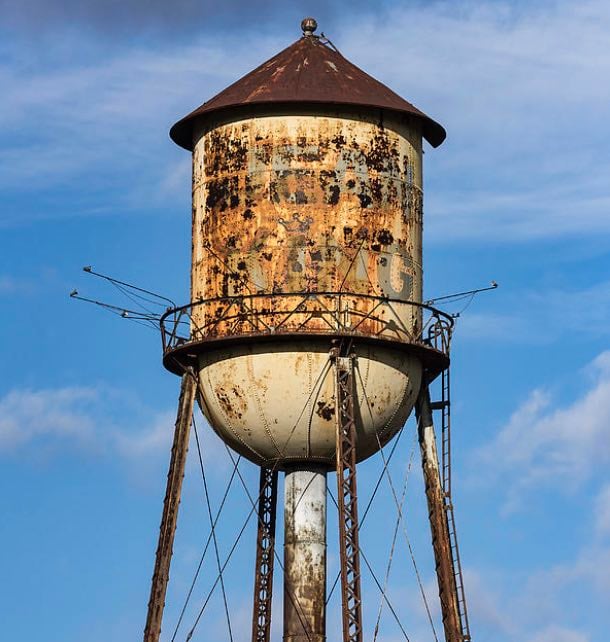

1. Surface and Substrate: Understand the type of surface or substrate that requires coating. Different materials, such as concrete, metal, wood, or plastics, have varying characteristics and may require specific coatings or surface preparation techniques.

2. Performance Requirements: Identify the desired performance attributes for the coating. Consider factors such as weather resistance, UV protection, durability, ease of cleaning, color retention, graffiti resistance, or fire resistance. Determine the specific needs of the project to ensure the chosen coating meets those requirements.

3. Aesthetic Considerations: Architects often prioritize the visual appearance of the coated surface. Consider aspects like color options, gloss levels, texture, or special effects to achieve the desired aesthetic outcome. Ensure the selected coating can provide the desired visual impact while also meeting performance requirements.

4. Environmental Considerations: Assess the environmental impact of the coating. Architects may seek eco-friendly or sustainable coating options that minimize volatile organic compound (VOC) emissions, have low environmental toxicity, or are made from renewable materials. Consider certifications or labels indicating environmental compliance. For example, Tnemec publishes a environmental product guide that lists VOC's, Red List materials, LEED listings, etc.

5. Compatibility with Other Materials: Determine the compatibility of the chosen coating with other materials or finishes present in the project. Some coatings may react adversely with certain materials or coatings, leading to compatibility issues or performance limitations. Ensure the coating can be applied without negatively affecting other elements of the design.

6. Application and Maintenance: Consider the practical aspects of coating application and long-term maintenance. Assess factors such as ease of application, drying or curing time, required surface preparation, and recommended maintenance procedures. A coating that is easy to apply and maintain can reduce construction time and ongoing maintenance efforts.

7. Industry Standards and Regulations: Familiarize yourself with industry-specific standards, building codes, or regulations that may impact the selection of coatings. Certain applications, such as healthcare or food facilities, may have specific requirements for cleanliness, hygiene, or chemical resistance that need to be met.

8. Supplier and Warranty: Engage with reputable coating suppliers that offer technical support, product documentation, and warranty information. Ensure the supplier has a proven track record and can provide the necessary assistance throughout the project's lifespan.

By considering these factors, architects can specify high-performance coatings that not only fulfill the project's functional requirements but also contribute to the overall design aesthetic and long-term performance of the coated surfaces. Collaboration with coating experts and suppliers can further assist in making informed decisions. Reach out to a High Performance Coating Consultant for a free consultation.

What an Engineer should know before spec'ing High...

There are many factors that should be considered...

Are High Performance Coatings Environmentally...

High-performance coatings can be environmentally...

What Maintenance is Required with High...

Maintenance requirements for high-performance...