Oneota Street Pump Station | High Performance Coatings

During replacement of the last pumping station built by Duluth, Minnesota, the Western Lake Superior Sanitary District (WLSSD) was able to rehabilitate the deteriorated concrete in an aging lift station using a high-build, fiber reinforced epoxy liner from Tnemec.

PROJECT INFORMATION

Project Location

Duluth, Minnesota

Project Completion Date

November 2007

Owner

Western Lake Superior Sanitary District

Architect / Engineer

MSA Professional Service - Duluth, Minnesota

Contractor / ApplicatorNorthland Painting of Duluth - Duluth, Minnesota

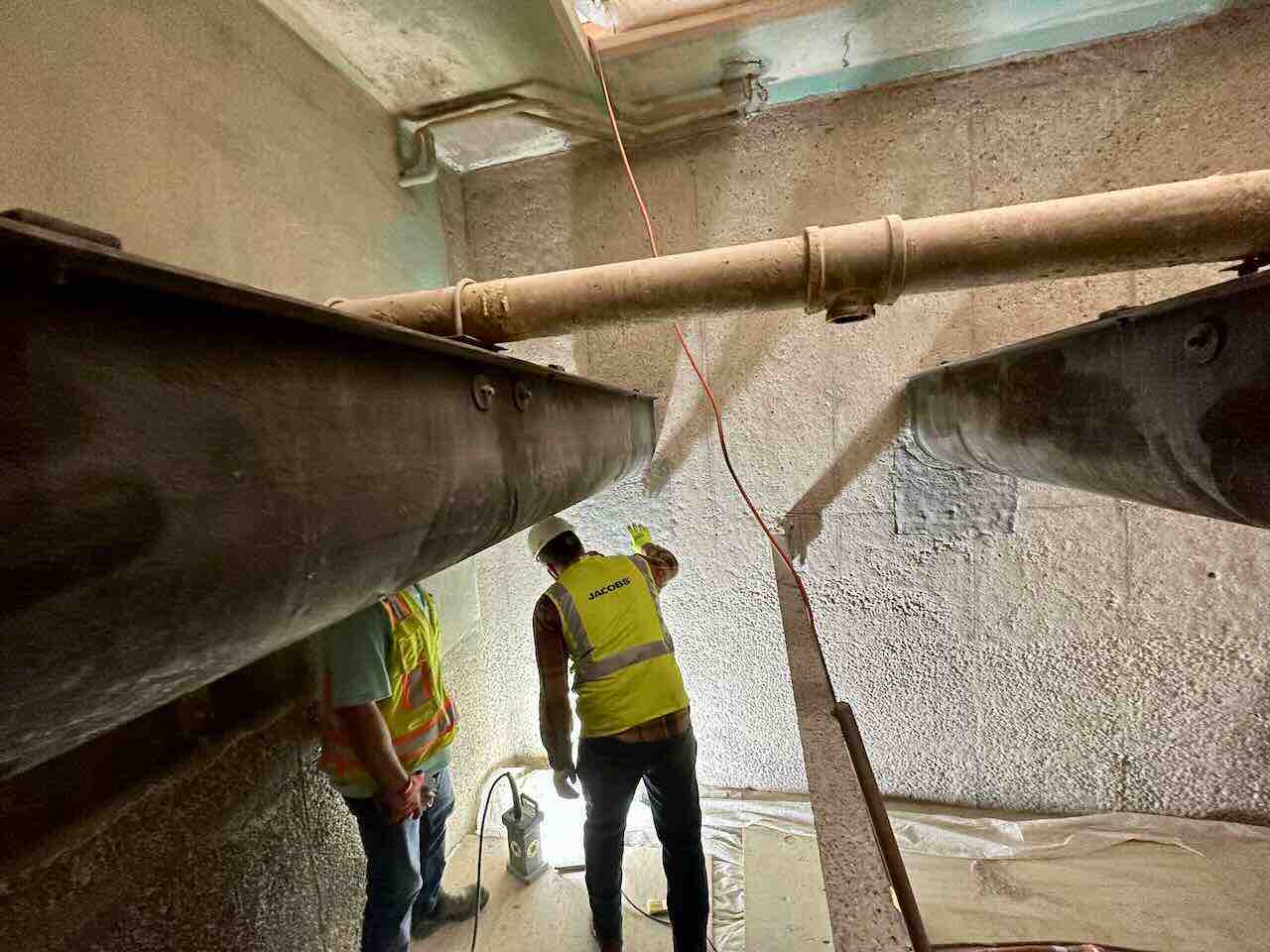

During replacement of the last pumping station built by Duluth, Minnesota, in the 1920s, the Western Lake Superior Sanitary District (WLSSD) was able to reha-bilitate the deteriorated concrete in an aging lift station using a high-build, fiber-reinforced epoxy liner from Tnemec. “The concrete in the lift station had corroded down to the river rock that was used as aggregate during mixing,” Tnemec coating consultant Randy Bartz observed. “The level of deterioration was indicative of wastewater facilities around the country that are looking for ways of maintaining or restoring infrastructure that was constructed many years ago.”

Prior to coating, the concrete was power washed and prepared in accordance with SSPC-SP13/NACE No. 6, ICRI-CSP5 Surface Preparation of Concrete. Next, the concrete was resurfaced with Series 218 MortarClad, an epoxy-modified cementi-tious mortar, which was trowel-applied at ¼-inch. “The concrete was especially corroded in the scum layer where there was as much as ½-inch of deterioration,” Bartz noted. “That’s where the coating contractor used a mason’s brush to scrub the mortar around the exposed aggregate.”

A topcoat of Series 436 Perma-Shield FR, a fiber-reinforced, 100 percent solids, modified polyamine epoxy liner, was spray-applied at 60 to 80 mils DFT. This high-build liner provides exceptional rehabilitative concrete corrosion protection from H2S gas permeation and biogenic sulfide corrosion found in severe waste-water systems. The fiber reinforcement in Series 436 offers flexural and tensile strength, making it ideal to use in domestic wastewater systems where high abra-sion and impact resistance are needed.

The restoration project was completed during winter months when the waste-water flow could be diverted from the lift station. “Ideally, we would like tem-peratures in the 50 degree range when we’re applying these coatings,” Bartz confirmed. “Given our winter weather in northern Minnesota, they had to pump indirect heat to the lift station to achieve proper cure.”

According to Bartz, municipal wastewater containment structures are being used well beyond their 40 to 50 year design life. “Many municipalities are looking for ways to maintain the infrastructure that they have while adding even more capaci-ty,” Bartz added. “They’re also concerned with containing odor, which contributes to an even more aggressive wastewater environment for coating systems that are used to protect concrete and steel from corrosion.”

Check out these additional resources on wastewater and water treatment coatings

Severe Wastewater Testing for Coatings

Ductile Iron Surface Preparation

Engineers- Specifying High Performance Coatings

Coatings for Wastewater Facilities

Don't miss these wastewater and water treatment coating project profiles

Howard Berry Water Treatment Plant

MORE HIGH PERFORMANCE COATINGS PROJECTS

Arvada Water Treatment Plant - NSF 600...

Project Overview: The Arvada Water Treatment Plant, located in [City, State], is a critical...

Market Type:

91st Avenue Wastewater Treatment Plant

For nearly half a century, the 91st Avenue Wastewater Treatment Plant (WWTP) has relied on just...

Market Type:

Cherryville WWTP Rehab

Creative Resurfacing's Cherryville North Carolina Wastewater Treatment Plant (WWTP) Rehabilitation...

Market Type:

OR

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL