Fargo WWTF Improvements and Expansion

Perma-Shield liners for H2S rich environments used to restore and protect wastewater structures.

PROJECT INFORMATION

Project Location

Fargo, North Dakota

Project Completion Date

2024

Owner

Engineer

Apex Engineering Group - Fargo, North Dakota

General Contractor

PKG Contracting, Inc. - Fargo, North Dakota

Installer

Protech Contracting Services - Fargo, North Dakota

Growth throughout the Red River Valley created opportunity to better the community with a facility large enough to accept wastewater from surrounding communities, establishing a regionalized WWTF. Future regulatory impacts were analyzed by Apex Engineer Group to pinpoint a treatment option allowing for the expansion of biosolids handling, treatment, storage and disposal facilities.

Phase I improvements to replace aging infrastructure on the existing east trickling filter train were constructed over a span of two years from 2015 to 2017. Phase II expanded the capacity of the facility, creating a regionalized wastewater treatment facility to service the surrounding area. The new west train meets future regulatory requirements set by the North Dakota Department of Health.

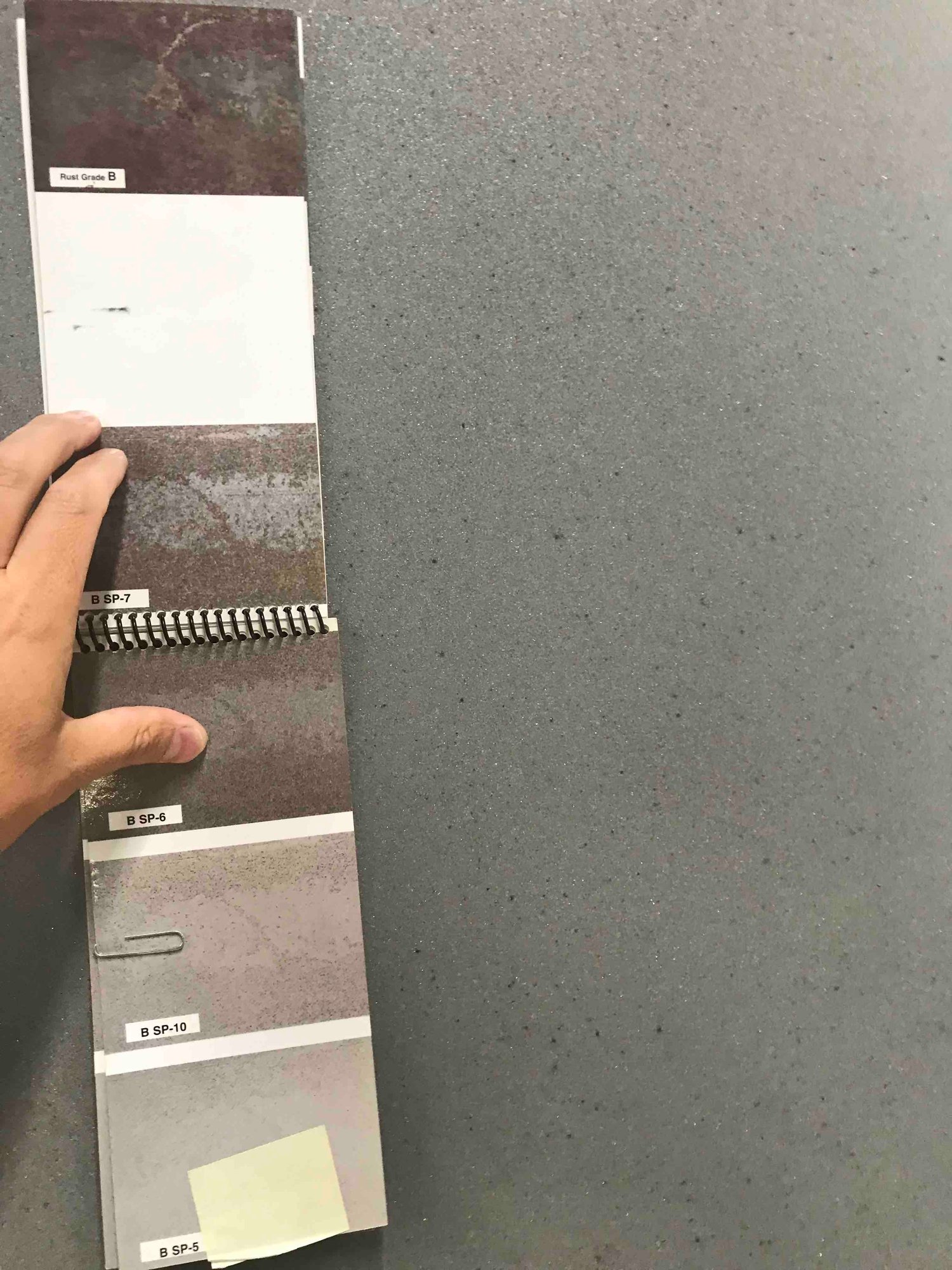

Existing structures in this facility were previously coated with products from a big box manufacturer that underperformed, failing within years of their application. Apex Engineer Group and the City of Fargo turned the experts at Tnemec Company for a suggestion on selecting coatings to restore corroded clarifiers and give them an extended life. After abrasive sandblasting per SSPC-SP13/NACE No. 6 Surface Preparation of Concrete, ICRI CSP 5 standards.

The concrete in the clarifier’s were restored with Tnemec Series 217 MortarCrete at a minimum of ½”. Series 218 MortarClad was then applied to mitigate the potential for outgassing and extensive pinhole repair in the finished liner. Due to Series G436 Perma-Shield FR’s excellent physical performance characteristics combined with its quantifiable data showing its ability to perform in aggressive wastewater environments via ASTM G210 it was selected as the liner to protect Fargo’s assets long-term.

For recoating clarifier equipment and coating of new steel digester covers steel was prepared per SSPC-SP10 Near-White Metal Blast Cleaning standards and then Series 1 Omnithane and Series 446 Perma-Shield MCU was applied to provide protection.

The facility expansion portion of this project included a new IFAS (Integrated Fixed-Film Activated Sludge) facility and new headworks building.

In total, over 2,200 gallons of Perma-Shield products was used to provide a long-lasting sustainable solution to mitigate corrosion due to the aggressiveness of wastewater environments.

Check out these additional resources on wastewater and water treatment coatings

Severe Wastewater Testing for Coatings

Ductile Iron Surface Preparation

Engineers- Specifying High Performance Coatings

Coatings for Wastewater Facilities

Don't miss these wastewater and water treatment coating project profiles

Howard Berry Water Treatment Plant

MORE HIGH PERFORMANCE COATINGS PROJECTS

Brightwater TreaTment Plant

Brightwater Treatment Plant was built to help treat the ever-growing demand and usage of water in...

Market Type:

.jpg)

alfred merritt smith water treatment facility

Originally built in 1971, the Alfred Merritt Smith Water Treatment Facility its at the base of Lake...

Market Type:

Oneota Street Pump Station | High...

During replacement of the last pumping station built by Duluth, Minnesota, in the 1920s, the...

Market Type:

OR

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL