91st Avenue Wastewater Treatment Plant

91st Avenue Wastewater Treatment Plant in Tolleson, Arizona.

PROJECT INFORMATION

Project Location

Tolleson, Arizona

Project Completion Date

Ongoing

Owner

City of Phoenix

Engineers

Malcolm Pirnie - Phoenix, Arizona

Black & Veatch -Phoenix, Arizona

GHD- Phoenix, Arizona

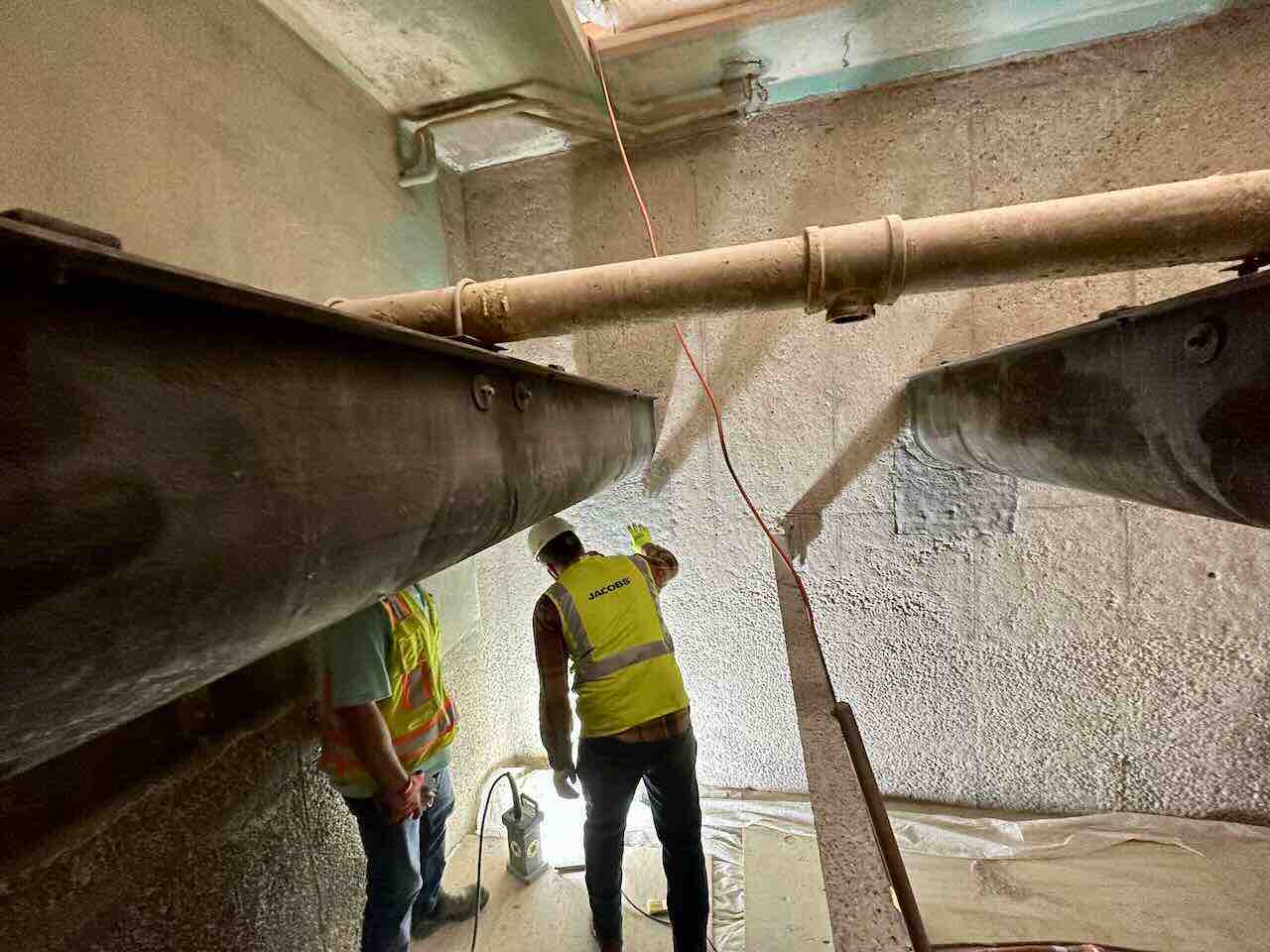

For nearly half a century, the 91st Avenue Wastewater Treatment Plant (WWTP) has relied on just about every product in Tnemec’s arsenal of protective coatings. “This is the largest wastewater treatment plant in Arizona and it has used a significant amount of our coatings since it opened,” according to Tnemec coating consultant Joe Keilbey. “We’ve been providing coatings for projects constantly there prior to 1985. At this facility they’ve probably used 90 percent of the coatings that Tnemec manufactures. Currently Tnemec coatings are being applied at the Unified Plant 2001 (UP01) and Unified Plant 2005 (UP05) areas.”

The plant disinfects wastewater from residential and business sources through a series of physical, biological and chemical treatment operations that include grit removal, sedimentation, aeration, clarification, disinfection and dechlorination. Among the diverse coatings applied throughout the plant’s vast infrastructure are:

• Epoxy systems for lining steel lids on the plant’s 24 anaerobic digesters, with their capacity for 3 million gallons of wastewater and sludge.

• Vinyl ester and aggregate-reinforced hybrid epoxy mortars for protecting concrete in headworks structures susceptible to corrosion attack, including influent channels, flow measurement facilities, bar racks and grit chambers.

• Two-component polyamide epoxies for immersion steel used in clarifier collectors, tank interiors and piping.

• Aliphatic polyurethanes for exterior exposed metals.

• StrataShield floor toppings and wall coating systems.

• Acrylics for exterior brick and masonry throughout the plant.

“Some of these coatings are used for maintenance of existing structures, but the bulk is for new construction,” Keilbey noted. “As the plant keeps expanding, we go in with new coatings. There have probably been 25 or 30 additions to the plant over the past twenty five years, including the two current projects. Tnemec is by far the preferred product out there.”

The 91st Avenue Plant serves the cities of Glendale, Mesa, Phoenix, Scottsdale and Tempe that make up the Sub-Regional Operating Group (SROG). The original 5 million gallon per day (mgd) 91st Avenue WWTP was built in 1958 and later replaced with a 45 mgd plant that was subsequently expanded throughout the years. The capacity of the 91st Avenue WWTP is now 179 mgd. An addition to the plant was started in 2001 that will boost the treatment capacity from 179 mgd to 204 mgd.

Tnemec coatings and repair materials continue to be utilized for repairs and maintenance of the 91st Avenue Plant. In late 2020, a new roof was installed on one of the digesters and the Perma-Shield system was applied to protect the concrete and steel. Superior SWAT product testing and long term proven performance made Tnemec the right choice.

Years of service in harsh wastewater environments can be hard on concrete assets, and there are times when repairs are needed.

Tnemec's Series 217 MortarCrete is a versatile repair mortar. Series 217 is a single-component, ultra rapid setting, hydraulic cementitious resurfacer used to restore deteriorated concrete surfaces or extended with aggregate to make high-strength concrete. The high early strength gain of this mortar and rapid setting allow this mortar to be coated with in 12 hours in many cases avoiding the costly time spent allowing traditional mortars hydrate.

Contact us to see how we can help you protect & maintain critical infrastructure assets.

Check out these additional resources on wastewater and water treatment coatings

Severe Wastewater Testing for Coatings

Ductile Iron Surface Preparation

Engineers- Specifying High Performance Coatings

Coatings for Wastewater Facilities

Don't miss these wastewater and water treatment coating project profiles

Howard Berry Water Treatment Plant

Scottsdale Groundwater Treatment Facility

MORE HIGH PERFORMANCE COATINGS PROJECTS

Cherryville WWTP Rehab

Creative Resurfacing's Cherryville North Carolina Wastewater Treatment Plant (WWTP) Rehabilitation...

Market Type:

Oneota Street Pump Station | High...

During replacement of the last pumping station built by Duluth, Minnesota, in the 1920s, the...

Market Type:

Arvada Water Treatment Plant - NSF 600...

Project Overview: The Arvada Water Treatment Plant, located in [City, State], is a critical...

Market Type:

OR

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL