Silver Spring Gardens | High Performance Coatings

Located in Eau Claire, Wisconsin, Silver Spring Gardens, Inc. is the world’s largest grower and processor of horseradish.

PROJECT INFORMATION

Project Location

Eau Claire, Wisconsin

Project Completion Date

April 2005

Owner

Silver Spring Gardens

Architect / Engineer

Excel Engineering - Fondulac, Wisconsin

Contractor / ApplicatorSwanson & Yongdale, Inc. - St. Louis Park, Minnesota

Located in Eau Claire, Wisconsin, Silver Spring Gardens, Inc. is the world’s largest grower and processor of horseradish. The family-owned company, a subsidiary of Huntsinger Farms, Inc., was founded in 1929 by Ellis Huntsinger when he started growing horseradish and other vegetable crops near Eau Claire. Back then, Huntsinger prepared the horseradish by hand

Today, Huntsinger Farms grows horseradish in a five-to-seven-year rotation with corn, soybeans, snap beans and other forage crops across more than 9,000 acres in both Wisconsin and Minnesota. The company is currently owned by Huntsinger’s granddaughter and great-grandsons.”

Tnemec teamed with Excel Engineering, Inc., and Swanson & Youngdale during the company’s large expansion in 2005 to specify a wall system that would be seamless, easy to clean and durable. Series 130 Envirofill, a waterborne cementitious acrylic, was used to fill the porous concrete where needed. Next, a prime coat of Series 201 Epoxoprime, a high-solids polyamine epoxy, was applied, followed by Series 270 Stranlok, a fiberglass-reinforced polyamine epoxy wall coating. Stranlok was chosen because it would meet the company’s needs, as well as withstand the frequent cleaning in the high-production food-processing facility. Stranlok can be applied in occupied spaces, cures quickly for fast return-to-service, and provides resistance to thermal shock, chemicals, impact and abrasion.

“Silver Spring needed an interior wall system that wouldn’t have any joints or seams to trap mildew or bacteria,” said Tnemec coating consultant Randy Bartz. “The coating system looks great and is easy to keep clean, which in turn helps to keep maintenance costs down.”

Series 607 Conformal Stain, a solvent-based acrylic, was chosen to protect the building’s exterior concrete. Series 607 exhibits excellent color stability and does not alter the natural texture of the surface.

MORE HIGH PERFORMANCE COATINGS PROJECTS

Darree Fields Elevated Storage Tank

As Dublin, Ohio, prepares for its bicentennial in 2010, residents and city officials were given an...

Market Type:

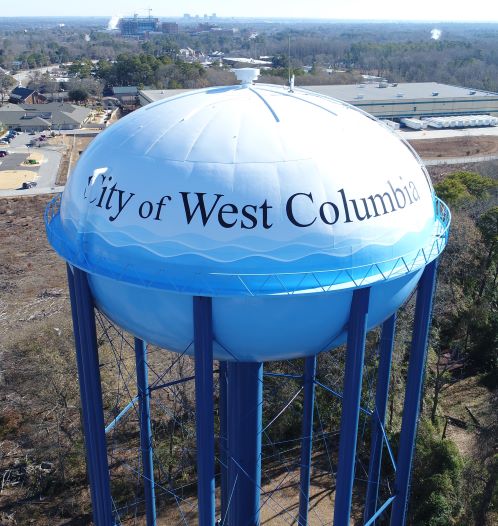

West columbia Pony Hill Tank

Just across the river from the capital city of Columbia, West Columbia, S.C., is home to more than...

Market Type:

Miami County Courthouse

“Due to the building’s historical significance, everyone wanted a protective finish that wasn’t...

Market Type:

OR

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL