Do Bolted Steel Tanks Last as Long as Welded Steel Tanks?

Bolted tanks and welded steel tanks are both commonly used for storing potable water and other liquids. Both have their own advantages and disadvantages.

- High Performance Coatings

Bolted water tanks and welded steel tanks are both commonly used for storing potable water and other liquids. However, there are some differences between these two types of tanks, and each has its own advantages and disadvantages.

- Sealing: Bolted water tanks rely on gaskets and sealants to create a tight seal between the tank panels. Over time, these seals can wear out, and water can begin to leak from the tank. Welded steel tanks, on the other hand, are welded together to form a continuous, leak-proof structure.

- Assembly: Bolted water tanks require a significant amount of assembly on site, as each panel needs to be bolted together. Welded steel tanks are fabricated off-site and transported to the installation location, then set on a foundation and welded together.

- Maintenance: Bolted water tanks require regular maintenance to ensure that the bolts remain tight and the gaskets and sealants are intact. Welded steel tanks, on the other hand, require less maintenance since there are no bolts or seals that can wear out over time.

- Corrosion: Bolted water tanks are typically made from coated steel panels, which can be susceptible to corrosion if the coating is damaged or compromised. Welded steel tanks are less susceptible to corrosion, since the steel is typically thicker and the welding process creates a more uniform structure.

Welded steel tanks are typically made from thicker steel plates and are fabricated off-site in a controlled environment, which can help ensure consistent quality and reduce the risk of defects. In addition, the welding process creates a continuous, leak-proof structure that is less prone to corrosion and other types of damage.

Bolted steel tanks, on the other hand, are assembled on-site from individual steel panels that are bolted together. While these tanks can be cost-effective and easier to transport and install, the bolted connections can be a potential source of leaks and corrosion over time.

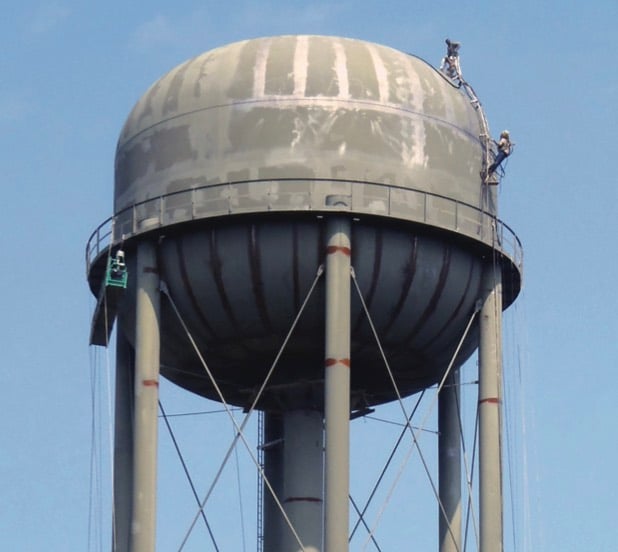

In general, a well-designed and properly maintained welded steel tank can last up to a century, while a bolted steel tank may have a shorter lifespan of 20-30 years, depending on design and maintenance. Overall, while bolted water tanks can be a cost-effective solution for storing water and other liquids, they will not be as durable or low-maintenance as welded steel tanks. A High Performance Coating Consultant can help determine which tank type may be best suited for your project and put you in touch with a fabricator that specializes in water tanks.

Check out these other resources on water tank coatings

Zinc Rich Primers in Potable Water

Cathodic Protection In Water Tanks

Don't Miss these project profiles on water tanks

What is Cathodic Protection in Potable Water...

What is Cathodic Protection in Potable Water...

Why Interior Dry Space Coatings Are Essential for...

Ensuring the longevity and safety of potable...

Interior Immersion Grade Coatings: Protecting...

Ensuring the longevity and safety of potable...