What is Cathodic Protection in Potable Water Tanks?

Discover how cathodic protection prevents corrosion in potable water tanks, ensuring structural integrity and safe water quality through innovative techniques and high-performance coatings.

- High Performance Coatings

What is Cathodic Protection in Potable Water Tanks?

Cathodic protection is a technique used to prevent corrosion in metal structures, such as potable water tanks, which are typically made of carbon steel, making them susceptible to corrosion when exposed to water and oxygen.

How does Cathodic Protection work?

Cathodic protection operates by introducing a small, controlled electric current to the metal structure, which effectively alters the electrochemical environment of the metal. This process shifts the corrosion potential of the metal to a more negative level, thereby reducing its tendency to corrode. Essentially, the metal becomes anodic, meaning it is less likely to undergo oxidation and subsequent deterioration. The electric current necessary for this protective measure is typically supplied by an external power source, such as a rectifier, which converts alternating current to direct current. This current is then carefully transmitted to the metal structure through a strategically arranged series of electrodes or anodes. These anodes are often made from materials that are more reactive than the metal being protected, ensuring that they corrode preferentially, thereby safeguarding the integrity of the primary metal structure. This method is meticulously designed to provide a consistent and reliable defense against the corrosive effects of water and oxygen, which are prevalent in environments such as potable water tanks.

What types of Cathodic Protection are used in Potable Water Tanks?

There are two main types of cathodic protection used in potable water tanks: impressed current cathodic protection and sacrificial anode cathodic protection. Impressed current cathodic protection is a sophisticated method that involves the use of an external power source, such as a rectifier, to supply a constant and controlled electric current to the metal structure. This current is carefully regulated to ensure that the entire surface of the metal is uniformly protected from corrosion. The system is designed to be highly adaptable, allowing for adjustments in current output to accommodate changes in environmental conditions or the specific needs of the tank. This type of protection is particularly effective for large or complex structures where uniform protection is critical.

On the other hand, sacrificial anode cathodic protection relies on the principle of galvanic corrosion, where a more reactive metal, such as zinc or magnesium, is strategically attached to the metal structure. These anodes are deliberately chosen for their higher reactivity compared to the steel of the tank, meaning they will corrode preferentially. Over time, the sacrificial anodes gradually deteriorate, releasing electrons that flow to the steel surface, thereby protecting it from corrosion. This method is often favored for its simplicity and ease of installation, as it does not require an external power source. The sacrificial anodes are periodically replaced as they are consumed, ensuring continuous protection of the steel structure. Both methods are crucial in maintaining the integrity and longevity of potable water tanks, each offering unique advantages depending on the specific requirements and conditions of the tank environment.

Why is Cathodic Protection used in Potable Water Tanks?

In potable water tanks, cathodic protection is a crucial and highly effective technique employed to maintain the structural integrity and durability of the tank over time. This method is essential for ensuring that the water stored within these tanks remains safe, clean, and free from any form of contamination that could compromise its quality. The primary function of cathodic protection is to prevent the onset and progression of corrosion, which is a natural and potentially damaging process that will occur over time if left unprotected .

By implementing cathodic protection, the lifespan of the tank is significantly extended, as the metal is shielded from the corrosive elements that would otherwise lead to its gradual deterioration. This protective measure is vital in reducing the risk of leaks, which can be a major concern in water storage systems. Leaks not only result in the loss of valuable water resources but also pose a threat of contamination, as they can allow external pollutants to enter the tank. Therefore, cathodic protection plays a pivotal role in safeguarding both the physical structure of the tank and the purity of the water it contains, ensuring that it remains a reliable and safe source of water for various applications.

Can High Performance Coatings Provide Cathodic Protection?

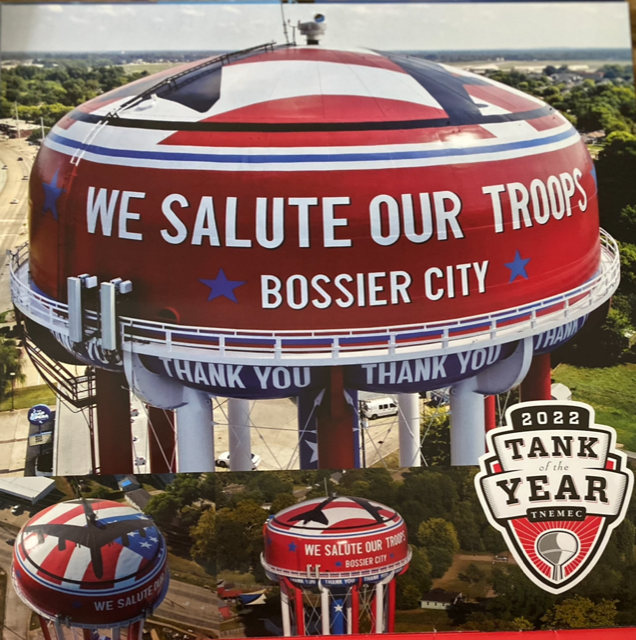

Zinc primer, like Tnemec Series 94-H20, will also provide cathodic protection to potable water tanks. Zinc is a highly reactive metal, which means that it is more likely to corrode than steel. When a zinc primer is applied to a steel structure, it forms a sacrificial layer that corrodes in place of the steel, providing cathodic protection.

During the corrosion process, the zinc in the primer is oxidized and dissolved, releasing electrons that flow to the steel surface. This process shifts the corrosion potential of the steel to a more negative level, which makes it less likely to corrode. The result is a protective layer that helps to prevent corrosion and extend the life of the steel structure.

In addition to providing cathodic protection, zinc primers are also known for their excellent adhesion and corrosion resistance properties. They are widely used in a range of industrial and commercial applications, including marine, offshore, and bridge construction, as well as successfully in potable water tanks service for the last 25 years.

When used in tandem with standard cathodic protection systems, zinc primer can add value to the long term corrosion protection and extend years of service to the water tank. Further, using both systems in the same tank provides a belt and suspenders approach to corrosion protection by ensuring if either fail, the other will perform in its place. For more information or project profiles with zinc primer in potable water tanks, reach out to a High Performance Coating consultant.

Check out these other resources on water tank coatings

Zinc Rich Primers in Potable Water

Don't Miss these project profiles on water tanks

Do Bolted Steel Tanks Last as Long as Welded...

Bolted water tanks and welded steel tanks are...

Interior Immersion Grade Coatings: Protecting...

Ensuring the longevity and safety of potable...

Protecting Your Investment: Why Fluoropolymer is...

Discover the unparalleled benefits of using...