What to know before putting a potable water tank out for bid?

Learn crucial steps for preparing a potable water tank painting project, including evaluations, procurement methods, coating selection, and quality control to ensure long-term success.

- High Performance Coatings

What to know before putting a potable water tank our for bid?

Was there a proactive and comprehensive inspection and evaluation of the tank? While this might seem like an obvious step, many tank projects are bid or completed without anyone thoroughly reviewing the tank. Some owners, engineers, and contractors simply reuse the specifications from their previous tank project. A seasoned and knowledgeable tank expert should always inspect a tank before defining the scope (and should be involved in quality control efforts throughout the project). Items that may need attention include tank locations and surroundings, necessary upgrades or repairs, structural concerns, existing coating conditions (such as generic type, mil thickness, adhesion, film issues, etc.), and associated tank components that may be affected or need rehabilitation. Addressing these items can help in developing the scope, painting options, budget, and schedule for a tank project. High-Performance Coatings consultants are always available to assist you in evaluating your tank needs.

How will the tank project be awarded?

There are several approaches to managing tank painting projects, each offering distinct pathways to achieving the desired outcome. Some owners prefer to handle the bidding and management processes themselves, taking full control over the project from start to finish. This approach allows them to directly oversee every aspect, ensuring that their specific requirements and standards are met. However, it also demands a significant investment of time and resources, as well as a deep understanding of the complexities involved in tank painting projects.

Alternatively, some owners choose to hire an engineer to manage the project. This method leverages the expertise and experience of professionals who are well-versed in the technical and logistical challenges of tank painting. Engineers can provide valuable insights into the best practices for surface preparation, coating selection, and application techniques, ensuring that the project is executed efficiently and effectively. This approach can alleviate the burden on the owner, but it may also involve additional costs associated with hiring external experts.

In some cases, contractors offer maintenance programs that include regular inspections, cleaning, and touch-ups to extend the life of the tank coatings. These programs can be particularly beneficial for owners looking to maintain their tanks in optimal condition over the long term, as they provide ongoing support and expertise. However, the success of such programs depends heavily on the reliability and reputation of the contractor, making it essential to choose a partner with a proven track record.

Additionally, some projects are negotiated, allowing for a more flexible and collaborative approach. This method involves discussions and agreements between the owner and the contractor to tailor the project scope, budget, and timeline to meet specific needs. Negotiated projects can foster a strong partnership and mutual understanding, but they require clear communication and trust between all parties involved.

Each of these methods has its pros and cons, and the choice of procurement method should be based on the owner's priorities, resources, and desired level of involvement. Regardless of the chosen approach, it is crucial to include a thorough tank evaluation and a robust project quality control program in the scope. This ensures that the project is not only completed to the highest standards but also meets the long-term performance and durability expectations.

What are the expectations for the tank?

Each tank is unique and therefore will have different budget, lifecycle, aesthetic, and performance requirements, which must be carefully considered to ensure the success of the project. Key questions to address before undertaking a major tank rehabilitation include:

- What is the budget, and how does it align with the financial constraints and goals of the project? Understanding the financial framework is crucial for planning and executing the project efficiently.

- What are the timeframe and schedule requirements, and how do they fit into the broader operational needs and timelines? This involves assessing the urgency of the project and coordinating with other ongoing activities to minimize disruptions.

- Will the interior, exterior, or both be addressed, and what are the specific challenges associated with each area? This decision impacts the scope of work and the resources required. Is an overcoat sufficient, or is a complete rehabilitation necessary, considering the current condition and future demands on the tank? Evaluating the extent of the work needed helps in determining the most effective approach.

- How many coats are required—one, two, or three—and what are the implications for durability and protection? The number of coats can affect the longevity and maintenance needs of the tank.

- Which materials will be used—acrylic, epoxy, fluoropolymer, urethane, or zinc—and how do they align with the environmental conditions and performance expectations? Selecting the right materials is vital for ensuring the tank's resilience and functionality.

- What type of signage, logo, or mural is needed, and in what colors, to meet branding or community engagement objectives? This involves considering the visual impact and messaging of the tank.

- Are there any other special requirements for the tank, such as compliance with regulatory standards or integration with existing infrastructure? Addressing these additional needs ensures that the project meets all necessary criteria and operates seamlessly within its environment.

Which coating systems will be used?

Once the tank conditions and expectations are thoroughly assessed, a suitable coating system can be carefully selected to meet the specific needs of the project. There is a wide array of options available for both interior and exterior coatings, each offering distinct advantages depending on the environmental conditions and performance requirements. It is highly advisable to design your coating system with a focus on product performance and the overall lifecycle cost, rather than simply opting for the initial "cheaper" options, which may not prove to be the most cost-effective in the long run. Cheaper coatings might require more frequent maintenance or replacement, leading to higher costs over time.

Therefore, a comprehensive evaluation of the coating's durability, resistance to environmental factors, and maintenance needs is crucial. Additionally, it is essential to ensure that the chosen coating system aligns with the owner's specific requirements and needs, taking into account factors such as aesthetic preferences, regulatory compliance, and operational demands. When evaluating specific coating systems, most modern tank projects now employ advanced materials such as zinc-rich primers, which provide excellent corrosion resistance; high-solids epoxy linings, known for their robust protective qualities; and fluoropolymers, which offer superior durability and weather resistance. These materials are selected for their ability to deliver optimal performance and significantly extend the lifecycle of the tank, ensuring that it remains in excellent condition for many years to come.

What quality control measures are in place?

Too often, tanks are completed with minimal quality control, which frequently involves just a cursory visual inspection once the work is done. This superficial approach can lead to overlooked issues that may compromise the tank's integrity and longevity. To ensure the tank is properly completed according to project specifications, it is crucial that someone thoroughly verifies that all aspects of surface preparation and application processes meet the required standards. This verification process can be performed by a qualified employee of the owner, an engineer, a third-party inspector, a tank contractor, or a coating manufacturer. Each of these professionals brings a unique perspective and expertise to the table, ensuring that every detail is meticulously checked. The key is that quality control and inspections are conducted transparently and in real-time with the project team, fostering an environment of open communication and collaboration. Any discrepancies, shortcomings, or non-conformances should be addressed and corrected immediately before proceeding to the next phase, preventing small issues from escalating into major problems.

Upon completion of each tank project, a formal final inspection should be conducted with all project team members to review and discuss the tank, ensuring that everyone is aligned on the project's outcomes and any potential areas for improvement. Additionally, an annual inspection should be performed one year later to ensure the workmanship and coatings are performing as intended, providing an opportunity to catch any early signs of wear or failure and address them proactively. This ongoing commitment to quality control not only safeguards the investment but also extends the lifespan of the tank, ensuring it remains a reliable asset for years to come.

While there isn't a straightforward solution for every tank project, applying the key points mentioned above can significantly enhance your next tank painting endeavor. If you are planning a water tank project and need assistance from an expert to refine your current tank painting methods, contact us at High Performance Coatings

Check out these other blogs concerning Potable Water Tanks:

Zinc Rich Primers in Potable Water Tanks

Check out these Potable Water Tank Project Profiles:

Washington State University Water Tank

West Columbia Pony Hill Water Tank

Do Bolted Steel Tanks Last as Long as Welded...

Bolted water tanks and welded steel tanks are...

Protecting Your Investment: Why Fluoropolymer is...

Discover the unparalleled benefits of using...

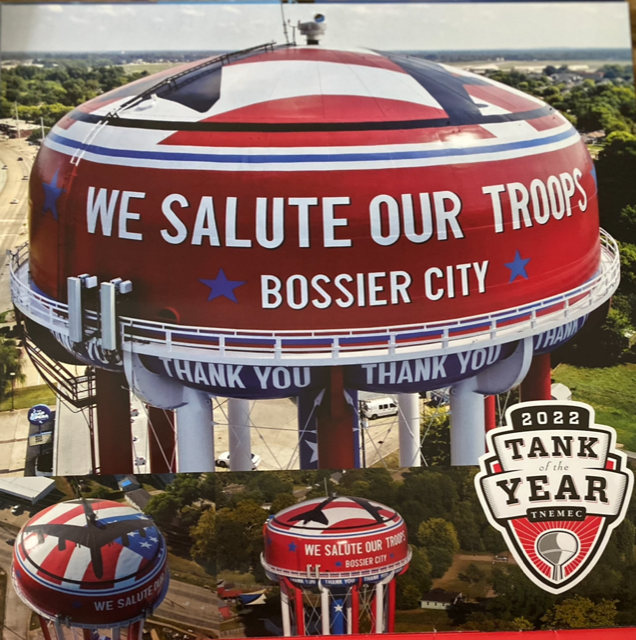

Inspiring Designs from Tnemec Tank of the Year...

Discover how the Tnemec Tank Contest showcases...