Writing performance based coating specifications

Specifiers are often tasked with reviewing product submittals where alternate materials differ from those listed in the project specification.

- High Performance Coatings

Specifiers are often tasked with reviewing product submittals where a contractor is attempting to submit alternate materials that differ from those listed in the project specification. This process is often timely and confusing since there are numerous coating manufacturers that supply similar generic coating technology.

The impetus behind an alternate product submittal often relates to contractor preference, material availability, and/or price. In some cases, the substitution request will meet the requirement of the project or environmental exposure. However, Architects, Engineers and Owners are trending toward specifying basis of design, performance based specifications to protect the quality of material used on a particular project.

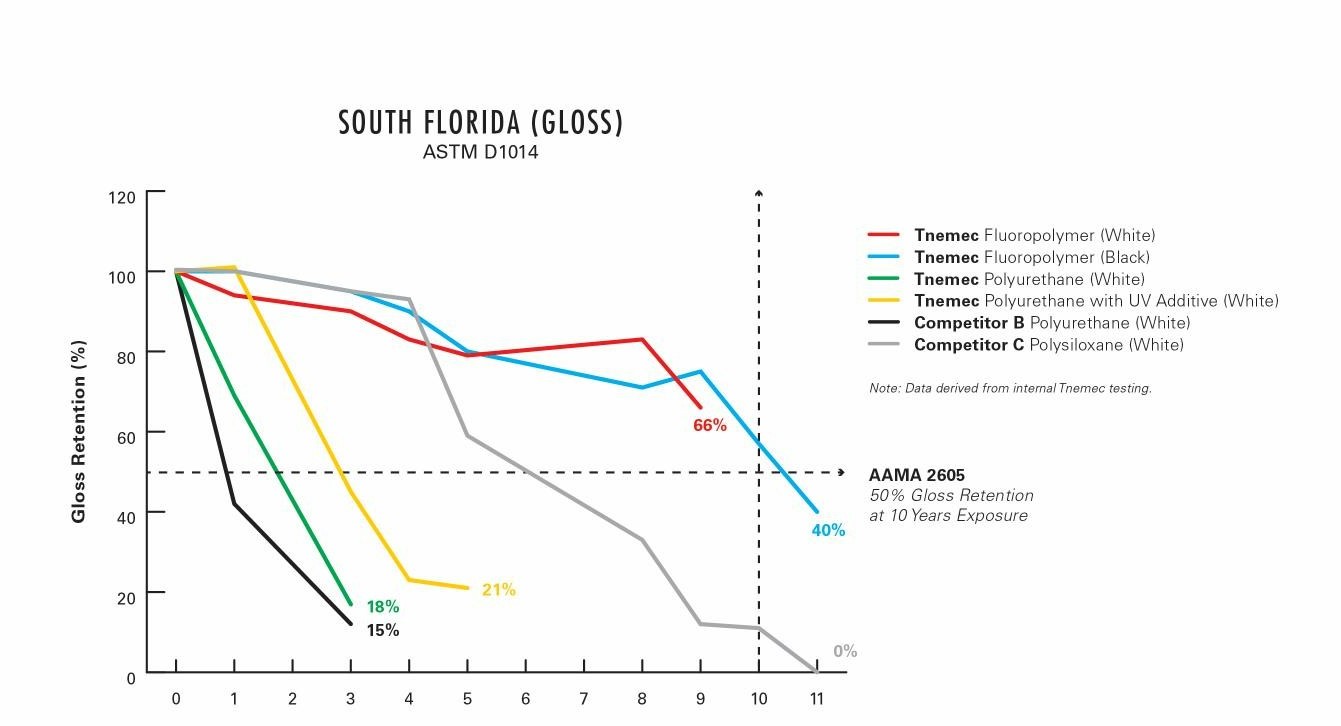

Like most manufactured goods, high-performance coating manufacturers can choose to manufacture products around price or quality. While two products can share a similar generic make-up, their performance can vary drastically depending on the types of raw materials that were used to build the product. The graphs included (measured in years of performance) show how drastically performance is effected when alternate raw materials are used to build the same product:

To compare product performance, coating manufacturers test their products in accordance to industry accepted performance standards from organizations like ASTM, ISO, UL, NSF, ANSI, and AMMA. The results of these real world or accelerated performance tests allows manufacturers, specifiers, contractors, and owners to evaluate and compare two similar products.

For reference, the performance criteria comparison below highlights how products with similar generic make-up can have considerably different performance traits:

Product Type: Moisture Cured Urethane, Zinc Rich

ASTM Test: B117 Salt Fog Testing

Manufacturer A Result: No blistering, cracking or delamination of film after 20,000 hours

Manufacturer B Result: No blistering, cracking or delamination of film after 5,000 hours

Product Type: Fluoropolymer Urethane

ASTM Test: D4141 Method C EMMAQUA

Manufacturer A Result: No less than 98% gloss retention, after 2,000 MJ/m² (88,095 MJ/m² total) EMMAQUA exposure

Manufacturer B Result: No less than 52% gloss retention, after 2,000 MJ/m² (88,095 MJ/m² total) EMMAQUA exposure

If the project specification isn’t protected by basis of design or minimum performance requirements, a contractor would be able to submit Manufacturer B on a project delivering a much lower performing coating system to the asset owner.

A project specification that is not protected by basis of design and/or a standard of quality will likely result in confusion during the bidding phase and lead to a time-consuming submittal review process.

By writing coating specifications around a standard of quality or basis of design, the specifier can eliminate the confusion during the bidding phase and simplify the submittal review process.

Contact your local High Performance Coating consultant to learn how to include relevant performance data into your next project specifications.

Check out these additional resources

Accelerated Weathering ASTM D4585

Don't miss these project profiles

Does formulation and product performance matter?

Why should you use performance criteria and basis...

What an Engineer should know before spec'ing High...

There are many factors that should be considered...

What is ASTM D4585 (Accelerated Weathering)...

ASTM D4585 is a standard practice developed by...