Have questions? Contact us!

INDUSTRIAL

WE WORK TO SUPPORT OWNERS, ENGINEERS, FABRICATORS AND CONTRACTORS WITH THE SELECTION OF COATING SYSTEMS FOR INDUSTRIAL PROJECTS OF ALL TYPES

Industrial facilities benefit from high performance coatings and linings which can protect assets, reduce downtime and improve operational efficiencies. Exposure-specific coating system selection can help maximize the life-cycles.

CHECK OUT OUR INDUSTRIAL PROJECTS

Filter and sort by market and/or client type to find the exact project specifications you’re looking for.

DO YOU NEED HELP UPDATING YOUR SPECIFICATIONS OR EVALUATING YOUR STRUCTURES?

Oil and Gas

Refineries and terminals have stringent environmental and API requirements for most assets. We assist with specifying specialized coatings to ensure regulatory compliance and the longest corrosion protection available.

- API 652 storage tanks

- Tank trailers

- Frac tanks

- Edge retentive technology

- Secondary containment

- High-temperature coatings

- Mud tanks

- Corrosion under insulation

Power Generation

Surfaces in fossil fuel and renewable power generation facilities face threats of corrosion, abrasion and chemical attack on a daily basis. We provide reliable protection against the harshest service conditions with applications that can reduce downtime and maintenance cost.

- Tank linings

- Floor coatings

- Secondary containment

- Surface tolerant coatings

- High-temperature applications

- Quick return to service

Mining

Metals and mining assets face some of the harshest conditions known today. Caustic and acidic environments, extreme weather, industrial waste, abrasion from tailings processing and erosion from mechanical abuse create the perfect environment for premature corrosion. Other common issues include primary and secondary containment of arsenic trioxide and heavy metals such as lead and cobalt. Thermal shock caused from hot acid and caustic are often extremely damaging to concrete building and plant superstructures.

- Concrete restoration

- Primary containment

- Dragline coating systems

- Abrasion resistant coatings

- Secondary containment

- Electro Winning

Bridge and Highway

Bridges and highways present unique challenges, often requiring highly effective corrosion protection systems to be applied in a manner that allows for quick return to service.

- Zinc rich coatings for galvanic corrosion protection

- Edge retentive coating formulations

- Deck coating systems

- Dry fall corrosion protection systems

Rail

Rail lines require protective coatings for structures and linings for tank car cargos. HPC consultants will assist with conditions assessment and specification development to meet the demands of each service type.

- Water-based coating systems

- Chemical resistant linings

- Direct-to-metal applications

- Surface tolerant coatings

- Impact and abrasion resistant floor coating systems

High Temperature Coatings

High temperature coatings are used to protect against a variety of exposures. These systems must resist corrosion and heat when applied to steel and stainless steel surfaces, and are often used in chemical processing plants, refineries, steel mills, power plants, and pulp/paper plants.

- Corrosion under insulation (CUI) prevention

- Dry fall formulations

- Protection for exposures up to 1200F

- Ambient and force cured options

PROJECT PROFILES: INDUSTRIAL

Featured project:

Williams Station Cooling Tower

The owners have used Tnemec for more than 30 years and were confident that Tnemec coatings would be the best choice for the revamped cooling tower.

Project Details:

- Location: Goose Creek, South Carolina

- Completion Date: September 1989

- Owner: South Carolina Electric & Gas

- Engineer: SCE&G Engineering of Goose Creek, South Carolina

MORE INDUSTRIAL PROJECTS

Lexington County Fire Academy

Lexington County was in search of the appropriate high-performance coating system to protect its...

Bellingham Washington Airport Hangar Floor

This project was undertaken for a private aviation hangar in Bellingham, Washington. The client...

Secondary containment coating systems in the...

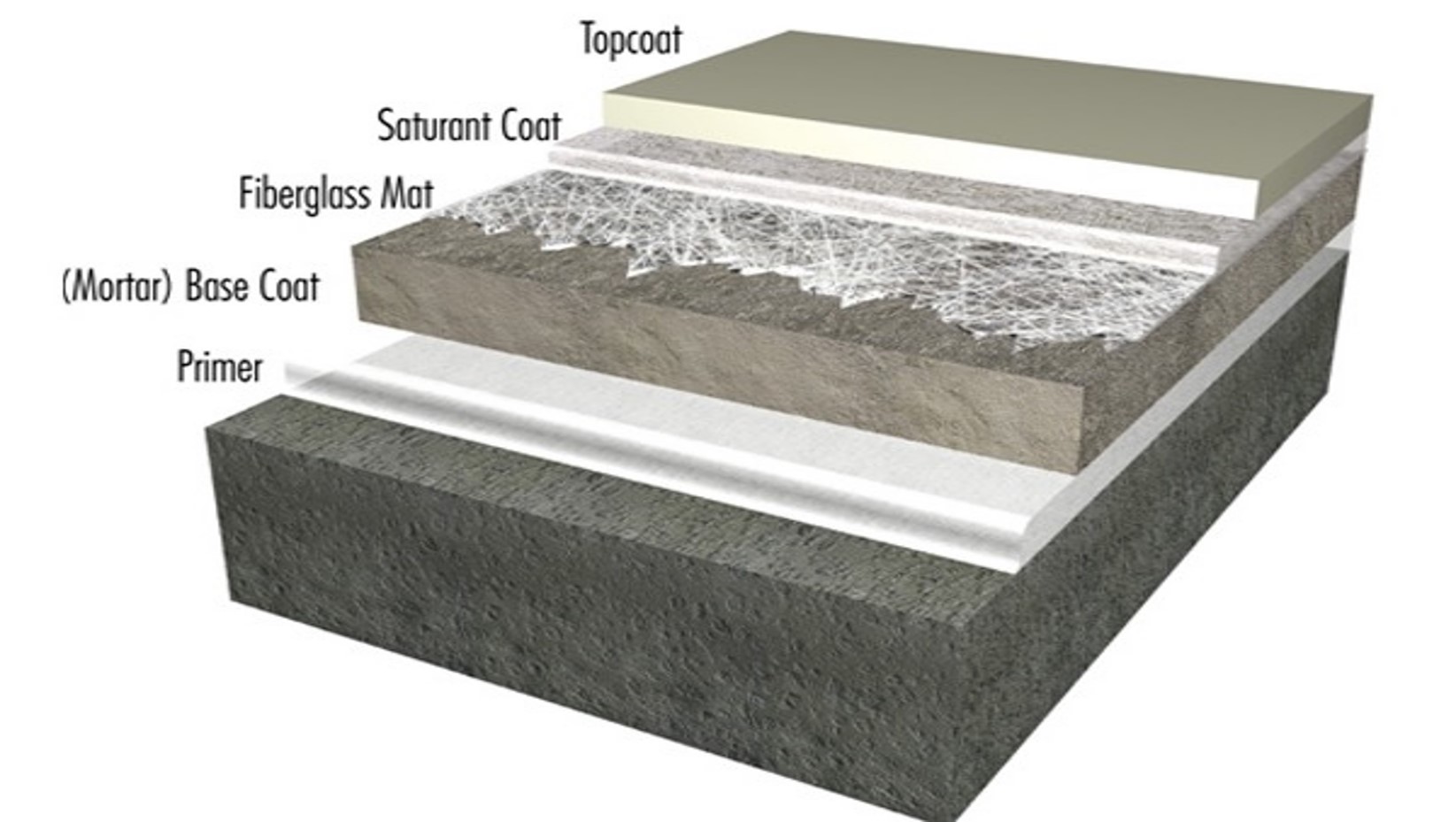

Here are some reasons why mortar/mat fiber-reinforced secondary containment coating systems...

NDSU Peltier Complex

NDSU's new Peltier Complex will provide a new home for:

High School Concessions and Restroom Floors

Steve Elliott and his team with Southern Painting and Maintenance Specialists did a great job of...

Manufacturing Facility Drum Wash Floors and Walls

Check out these other resources

Town of Gilbert NWTP Containment

When the time came to re-work the secondary containment area at Gilbert's NWTP, WaterWorks...

Duke Energy's Cowans Ford Hydro Dam Gates Rehab

This massive 15 million dollar hydro plant rehab took over 4 years to complete and included...

Mine Slurry Tank

Industrial mining operation projects are always built around minimizing downtime and operational...

Conagra Peeler Tanks | High Performance Coatings

ConAgra Brands, a food processing and packaging company headquartered in Chicago, expanded into...

PHILADELPHIA RAIL PARK

“The project involved turning this rail line, consisting of rusted steel and overgrown weeds, into...

York Water Pipe Gallery

Founded in 1816, York Water Company has been serving its local community for almost 200 years and...

See our other market segments:

GET UPDATES SENT DIRECTLY TO YOUR INBOX TO STAY CURRENT WITH INDUSTRY STANDARDS AND NEW PRODUCTS.

High Performance Coatings strives to be on the cutting edge of coating technology. As experts within our field we bring the latest innovations to our customers in coatings solutions for each new project.