What Are The Benefits of Protective Coatings On Carbon Steel Pipelines

Discover why coating carbon steel pipelines with High Performance Coatings are essential for long-term durability, efficiency, and cost-effectiveness.

- High Performance Coatings

Discover why coating carbon steel pipelines is essential for durability, efficiency, and cost-effectiveness.

Enhancing Durability and Longevity

Coating carbon steel pipelines significantly enhances their durability and longevity. High-performance coatings act as a protective barrier against external elements, which can otherwise cause rapid deterioration. This added layer of protection ensures that the pipelines can withstand harsh environmental conditions, mechanical stress, and other potential damage, thereby extending their operational lifespan.

In addition, coatings help in maintaining the structural integrity of the pipelines over time. Without adequate protection, carbon steel is susceptible to wear and tear, which can lead to costly repairs or replacements. By investing in high-performance coatings, companies can ensure that their pipeline infrastructure remains robust and reliable for many years.

Preventing Corrosion and Metal Loss

One of the primary benefits of coating carbon steel pipelines is the prevention of corrosion and metal loss. Corrosion is a natural process that occurs when metal reacts with environmental elements such as water, oxygen, and chemicals. This reaction leads to the gradual degradation of the metal, compromising the pipeline’s integrity and performance.

High-performance coatings provide a protective layer that prevents these elements from coming into direct contact with the metal surface. This significantly reduces the risk of corrosion, ensuring that the pipelines remain intact and functional. By mitigating corrosion, coatings help in preserving the metal's strength and thickness, thereby preventing metal loss and extending the pipeline's service life. Zinc primers, like Tnemec Series 94-H20 or Series 90-97 can provide cathodic protection. But many times, two coats of epoxy, like Tnemec Series N140 or Series 21 will provide excellent protection and meet AWWA C210. If UV resistance is required, a finish coat of urethane, like Tnemec Series 1095 can be a good choice.

Improving Safety and Reducing Maintenance Costs

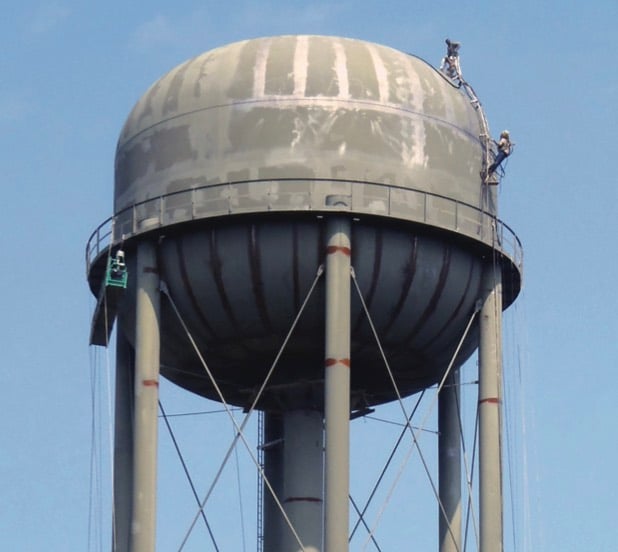

Coating carbon steel pipelines contributes to improved safety and reduced maintenance costs. Unprotected pipelines are prone to leaks, bursts, and other failures, which can pose significant safety hazards, including environmental contamination and risks to human health. High-performance coatings mitigate these risks by providing a robust protective layer that prevent damage and degradation over time.

Furthermore, coated pipelines require less frequent maintenance and inspections, as the protective layer reduces the likelihood of damage and deterioration. This translates to lower maintenance costs and fewer disruptions in pipeline operations. By investing in high-performance coatings, companies can achieve a safer and more cost-effective pipeline infrastructure.

Boosting Environmental Protection

Coating carbon steel pipelines plays a crucial role in boosting environmental protection. Uncoated pipelines are more susceptible corrosion over time, which may cause leaks and spills, which can lead to soil and water contamination. Such environmental incidents can have long-lasting negative effects on ecosystems and public health.

High-performance coatings prevent corrosion by maintaining the integrity of the pipelines, thereby reducing the risk of environmental contamination. By ensuring that pipelines are well-protected, companies can demonstrate their commitment to environmental stewardship and sustainability. Coatings not only safeguard the pipelines but also contribute to the protection of the surrounding environment.

AWWA C210 in a Glance

The American Water Works Association (AWWA) C210 standard provides guidelines for the application of liquid epoxy coatings to steel water pipelines. This standard is widely recognized and followed in the industry to ensure the quality and effectiveness of pipeline coatings.

AWWA C210 covers various aspects, including surface preparation, coating application, and inspection procedures. By adhering to this standard, companies can ensure that their pipeline coatings meet the required specifications and provide optimal protection. The AWWA C210 standard serves as a valuable reference for achieving high-performance and durable coatings for carbon steel pipelines.

If you require assistance in specifying coatings for pipelines, both above and below grade, contact us here for a free assessment and specification review..

Exploring Coatings in AWWA C210 Standard

Unlock the secrets of enhanced pipeline longevity...

Interior Immersion Grade Coatings: Protecting...

Ensuring the longevity and safety of potable...