Decoding High Performance Coatings: A Comparative Analysis

Explore the cutting-edge world of high performance coatings, understanding their pivotal roles and comparative advantages in modern industries.

- Rick Gilbreath

Explore the cutting-edge world of high performance coatings, understanding their pivotal roles and comparative advantages in modern industries.

Understanding High Performance Coatings and Their Critical Applications

High performance coatings are engineered for superior durability, resistance, and longevity compared to conventional paint products. These specialized coatings serve as a protective barrier against environmental factors such as corrosion, UV radiation, and chemical exposure. In industries where material performance is critical—such as in marine, automotive, aerospace, and infrastructure—high performance coatings ensure safety, functionality, and cost-efficiency over the long term.

The importance of these coatings cannot be overstated, as they are integral to maintaining the structural integrity and operational reliability of equipment and structures. By safeguarding assets from degradation, these coatings extend their lifecycle, reduce maintenance costs, and minimize the environmental impact through less frequent replacements and repairs.

Comparative Analysis of Key High Performance Coatings in Different Industries

High performance coatings vary greatly in composition and application, tailored to meet the unique demands of different industries. For instance, epoxy coatings are renowned for their strength and chemical resistance, making them ideal for industrial flooring, tanks, and pipes. Polyurethane coatings, on the other hand, offer excellent weather-ability and are often used for exterior surfaces that require a balance of durability and aesthetics.

Silicone-based coatings are favored in high-temperature environments due to their thermal stability. Meanwhile, fluoropolymer coatings are selected for their exceptional resistance to UV and solvents. Each type of coating brings its own set of advantages to the table, necessitating a thorough analysis to determine the most suitable option for a given application.

Evaluating the Durability and Sustainability of Various Coatings

When assessing the performance of high performance coatings, two key factors to consider are durability and sustainability. Durability encompasses the coating's ability to withstand physical and chemical stress over time, which directly impacts the frequency of re-application and maintenance work. Sustainability, on the other hand, refers to the environmental footprint of the coatings, including the resources used in their production, their longevity, and the potential for recycling or safe disposal.

Modern coatings are increasingly formulated to be more eco-friendly, with lower volatile organic compound (VOC) emissions and higher solids content. This shift not only reduces the environmental impact but also complies with stricter regulations while maintaining high-quality performance.

The Role of Technology in Advancing Coating Performance and Efficiency

Technological advancements have played a pivotal role in improving the performance and application efficiency of high performance coatings. Innovations such as nanotechnology have led to the development of coatings with enhanced protective properties, like self-healing surfaces and improved scratch resistance. Smart coatings, which can change their properties in response to environmental stimuli, represent another leap forward, offering dynamic protection and potentially signaling when maintenance is required.

Automation and improved application techniques have also contributed to increased efficiency during the coating process, ensuring more consistent coverage, faster curing times, and reduced labor costs. Such technological progress supports the industry's move towards sustainable, high-performing solutions that meet the ever-growing demands of various sectors.

Case Studies: Success Stories and Lessons Learned from High Performance Coatings

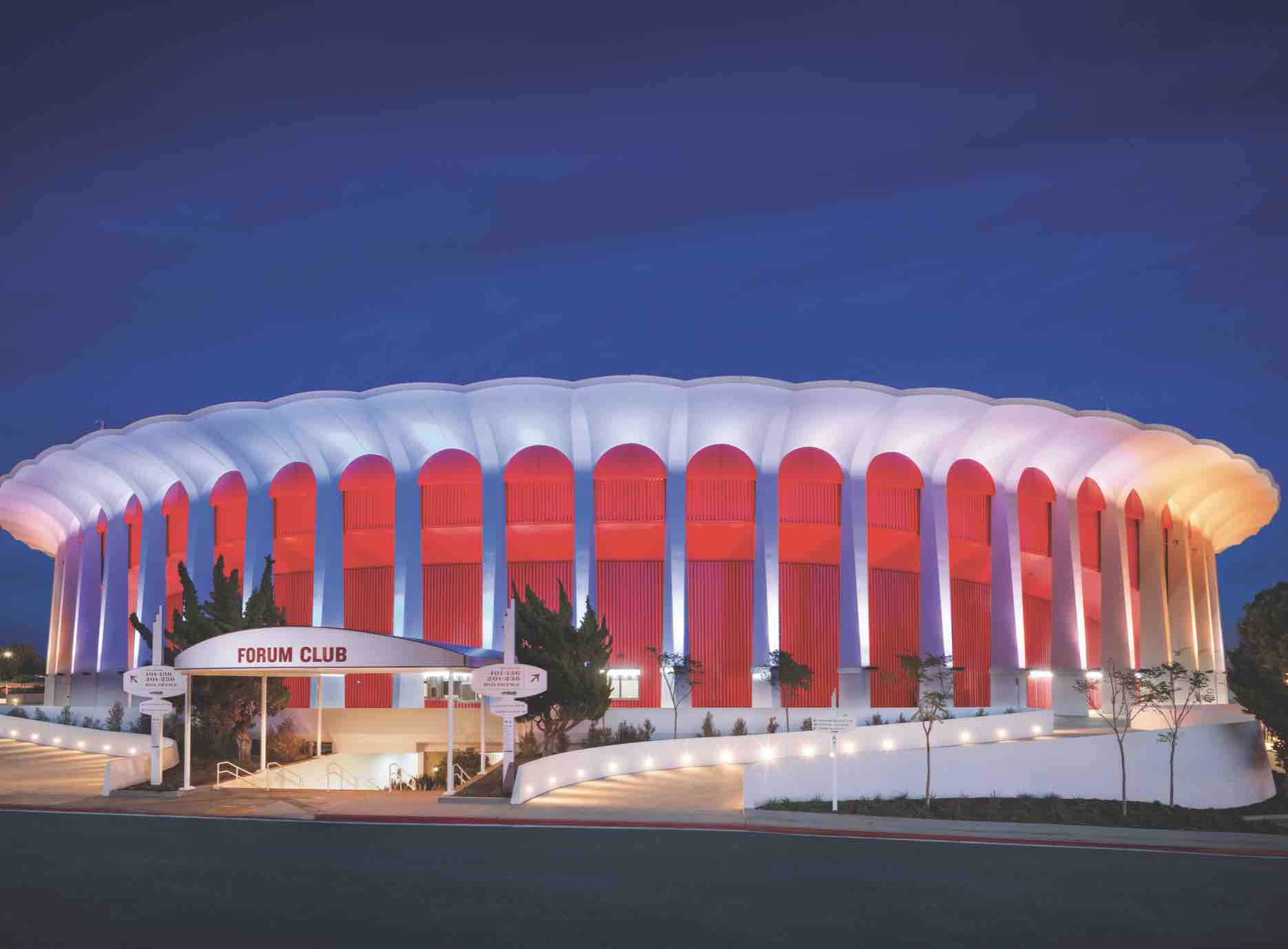

Real-world applications of high performance coatings provide valuable insights into their benefits and limitations. For example, Tnemec coatings have been used in numerous projects, from water tanks to bridges, where they have demonstrated exceptional longevity and resistance to harsh conditions. These case studies highlight the importance of selecting the right coating system for specific environmental stresses and substrate types.

Lessons learned from these applications underscore the need to properly prepare surfaces, apply coatings according to specifications, and perform regular inspections to maximize the lifespan of the coating system. As the industry evolves, these case studies serve as benchmarks for quality and performance, guiding future innovations and best practices.

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL

Check out these other resources on this topic:

What is ASTM B117 (Salt Fog) Testing and Why is...

What is ASTM B117 Salt Fog Testing?

ASTM B117...

Here's a cheat sheet for ASTM coating testing...

This blog contains ASTM Standards to compare...

What is ASTM D4547 (QUV Exposure) Testing and Why...

ASTM D4587 (QUV Exposure) refers to a specific...