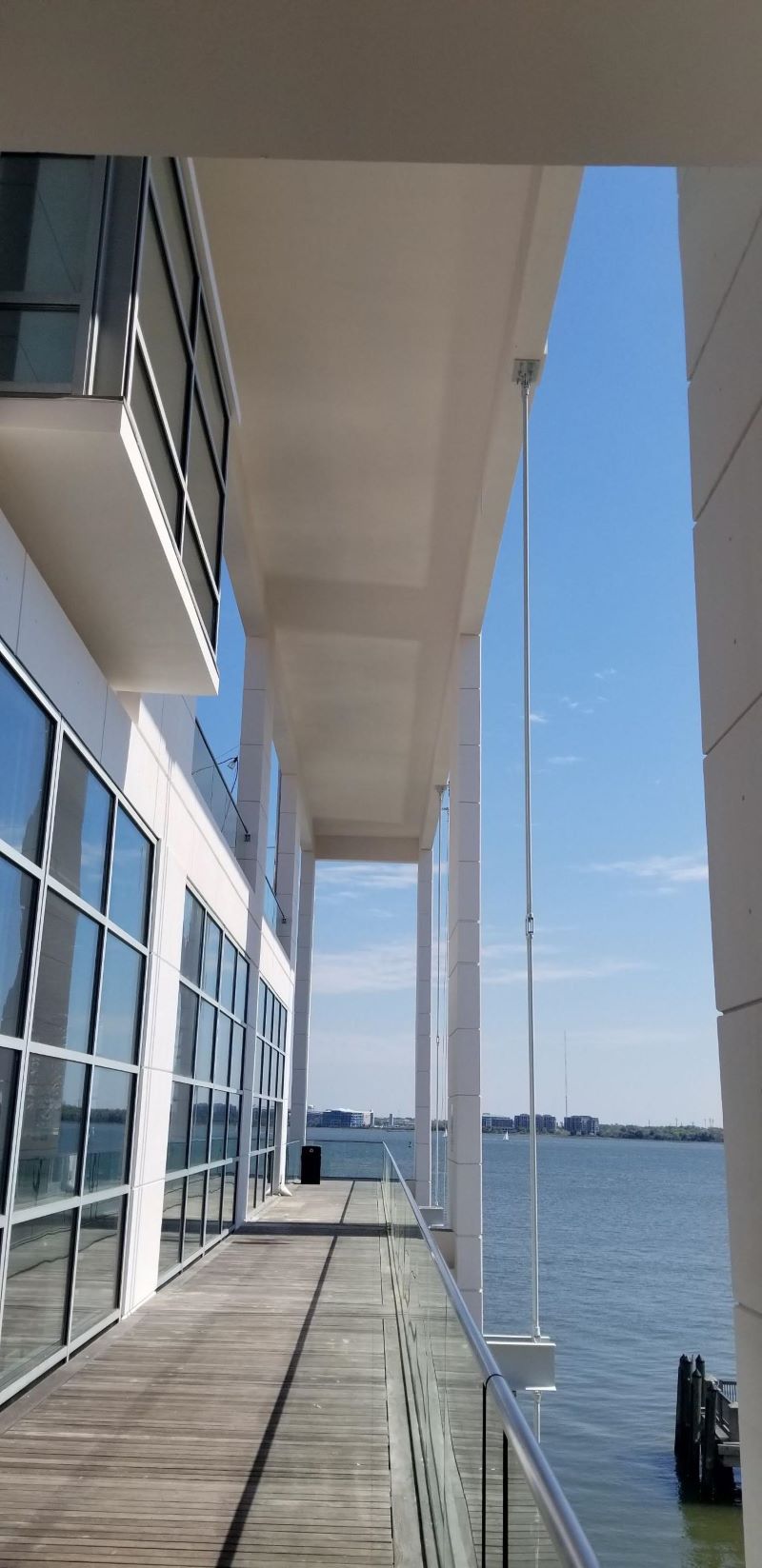

South Carolina Aquarium Exterior Repaint

In 2017, the aquarium received funding for renovations and a full exterior repaint.

PROJECT INFORMATION

Project Location

Charleston SC

Project Completion Date

2017

Owner

Architect

Contractor

Installer

In 2017, the South Carolina Aquarium received funding for renovations and a full exterior repaint. The once-pristine white concrete exterior walls had become grimy and taken on a mildewed appearance along the edges, and the steel surfaces had become dull due to the environmental conditions. The old coatings had passed the point where a simple cleaning would solve the aesthetic problems.

A number of issues complicated the exterior repainting project. For one, the aquarium sits on the ocean and the Ashley River, meaning any coatings would need to stand up to the marine environment and any tropical or hurricane-type weather that blows through.

%20(2).jpg?width=580&name=Charleston%20Aquarium%20(3%20of%203)%20(2).jpg)

Along with its oceanside location, the aquarium is within the historic district of Charleston, a beautiful area that comes with a number of different parties whose approval is needed before any rehabilitation work could begin. Charleston places a heavy emphasis on preserving the historic character of the city and legally mandates that there be a historic preservation component in the planning and execution as part of the planning process for construction projects in the area.

Finally, the coatings would be covering areas where animals normally live. In some cases, animals would need to be displaced for coatings to be applied. Dealing with marine creatures means that a simple move to a new area isn’t really so simple: constraints such as the type and depth of water necessary for the survival of each animal, as well as the need to keep certain animals apart from each other.

With all of these considerations in mind, it was imperative that any coatings be both safe for the environment and the animals as well as last as long as possible so this process wouldn’t need to be repeated again any time soon.

Tnemec products had already been used with great success inside the aquarium, especially when used in 2017 to coat the sea turtle containment structures. Tnemec was able to recommend the right system to handle the conditions of caring for sick sea turtles.

So, when the aquarium was looking for the right coatings for this new job, project managers reached out to Nick Vause, local Tnemec representative, knowing that he’d provide the right combination of expertise and products for the aquarium’s needs. One coatings system was needed for the exterior steel framing for the building, and another system for the concrete walls and surrounding areas.

For the steel surfaces, Vause recommended a system featuring Fluoronar. Tnemec developed Fluoronar with protection in mind. It’s a premium fluoropolymer topcoat which is designed to give long-term protection while retaining its aesthetic qualities for decades.

Steel surfaces were spot primed with Series 135 Chembuild, a modified polyamidoamine epoxy. This high-build coating adheres tightly to old coatings and marginally prepared rusty steel surfaces and provides excellent resistance to abrasion, chemicals and corrosion. After spot priming, a full coat of Series 135 was applied at a high build of 4-6 mils DFT.

Steel surfaces were then finished with a topcoat of Series 1070 Fluoronar, which was roller- and brush-applied at 2-3 mils DFT. A high-solids fluoropolymer coating, Series 1070 has excellent color and gloss retention even in extreme environments.

The exterior precast concrete needed a much different system. First, concrete was patched up and sealed with Series 151-1051 Elasto-Grip FC. This waterborne modified polyamine epoxy is a flexible, penetrating, and low-odor primer designed for porous substrates such as cement.

Once the concrete was sealed, primed, and ready, the contractors applied two full coats of Series 156 Enviro-Crete, a modified waterborne acrylate. Series 156, true to its name, is able to stand up to big shifts in the outdoors environment; its elastomeric properties provide protection against the seasonal freezing-thawing cycles, sunlight, and the intense rains of South Carolina’s summers and occasional tropical storms. Series 156 can also help fill and bridge minor hairline cracks. Combined with the bonding properties of Series 151-1051, Series 156 will provide a lasting and beautiful finish for the concrete exterior of the aquarium for decades to come.

Phillips Industrial, a local coatings contractor, completed the coatings applications on time while dealing with a variety of challenges from the environment. The owners, project crew and architects all agreed that the final results are excellent.

MORE HIGH PERFORMANCE COATINGS PROJECTS

Lit Brothers Building

After closing its doors in 1977, the Lit Brothers Department Store in Philadelphia was a prime...

Market Type:

Oneota Street Pump Station | High...

During replacement of the last pumping station built by Duluth, Minnesota, in the 1920s, the...

Market Type:

Miami County Courthouse

“Due to the building’s historical significance, everyone wanted a protective finish that wasn’t...

Market Type:

OR

LET OUR KNOWLEDGE AND EXPERTISE HELP ENSURE YOUR NEXT PROJECT IS SUCCESSFUL